- No products in the cart.

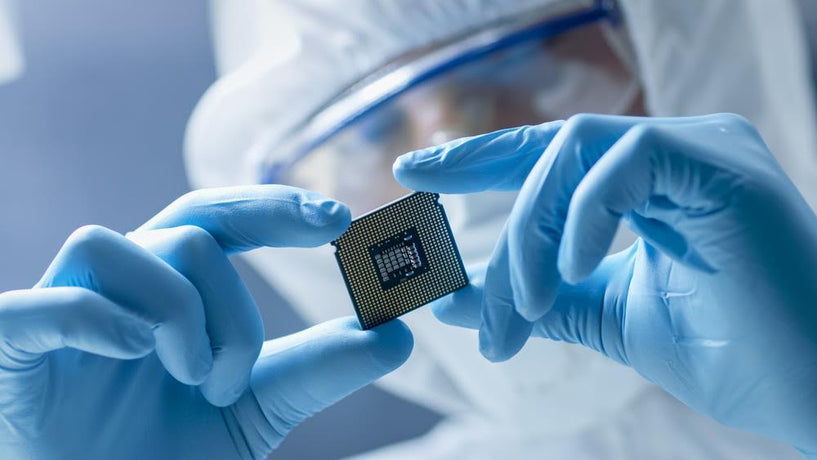

In the intricate world of semiconductor manufacturing, maintaining an ultra-clean environment is paramount. Even the tiniest particle can disrupt the delicate processes involved in creating semiconductors, leading to defects and reduced yields. One crucial tool in the pursuit of cleanliness and protection within semiconductor fabs is the cleanroom wipe. In this blog, we will explore the significance of cleanroom wipes, focusing on the CPSVP09098 Berkshire CapSure-VP Knitted SE Wiper and Texwipe polyester cleanroom wipes as examples of cutting-edge solutions.

The Importance of Cleanroom Wipes

Semiconductor fabs operate in cleanrooms, environments with controlled levels of airborne particles to ensure the integrity of the manufacturing processes. Cleanroom wipes play a pivotal role in maintaining these stringent cleanliness standards. These wipes are designed to effectively remove contaminants such as dust, lint, and other particles from surfaces without introducing additional contaminants.

Cleanroom wipes come in various materials, each serving a specific purpose. Polyester cleanroom wipes, in particular, are widely used for their low particle generation, chemical resistance, and high absorbency. These qualities make them ideal for critical cleaning applications in semiconductor manufacturing.

The Role of Cleanroom Wipes in Fab Processes

Cleanroom wipes are used for a variety of tasks in fabs, including:

- Cleaning surfaces: Wipes are used to remove dust, fingerprints, and other contaminants from tools, equipment, and work surfaces.

- Applying and removing chemicals: Wipes are used to apply and remove photoresists, developers, and other chemicals used in the fabrication process.

- Wiping down tools and equipment: Wipes are used to clean and disinfect tools and equipment between uses.

- Cleaning spills: Wipes are essential for quickly and effectively cleaning up spills of chemicals or other materials.

Choosing the Right Cleanroom Wipe for the Job

Not all cleanroom wipes are created equal. When choosing wipes for your fab, it is important to consider the following factors:

- Material: Cleanroom wipes are typically made from non-woven fabrics such as polyester, nylon, or polypropylene. These materials are low in linting and extractables, meaning they are less likely to leave behind particles that could contaminate the environment.

- Knit vs. woven: Knit wipes are softer and more absorbent than woven wipes, making them ideal for delicate tasks such as cleaning surfaces. Woven wipes are stronger and more durable, making them better suited for tasks such as scrubbing or applying chemicals.

- Size and shape: Cleanroom wipes come in a variety of sizes and shapes to meet the specific needs of different tasks. For example, small wipes are ideal for cleaning tools and equipment, while large wipes are better for cleaning spills.

- Chemical compatibility: Some cleanroom wipes are treated with chemicals that make them resistant to specific solvents or acids. Be sure to choose wipes that are compatible with the chemicals you will be using.

Berkshire CPSVP09098 CapSure-VP Knitted SE Wiper

The CPSVP09098 Berkshire CapSure-VP Knitted SE Wiper stands out as a notable example of a cleanroom wipe engineered for excellence in semiconductor fabs. This wipe is constructed using a state-of-the-art knitted process, resulting in a fabric with minimal fiber shedding and excellent durability.

The unique design of the CapSure-VP wiper allows for efficient particle entrapment, ensuring that contaminants are captured and removed from critical surfaces. This is crucial in semiconductor manufacturing, where even a tiny particle can lead to defects in the final product.

Furthermore, the CapSure-VP wiper is compatible with a variety of cleaning agents, making it versatile for different cleaning applications within the cleanroom. Its ability to maintain cleanliness while effectively removing residues and contaminants makes it a valuable asset in semiconductor fabs.

Texwipe TX8949 Polyester Cleanroom Wiper

Texwipe TexVantage Polyester Wiper 9" x 9" Sealed Edge - TX8949 Cleanroom Wiper, providing a robust solution for specific cleanroom tasks. This wipe is crafted from a strong, woven polyester fabric, making it ideal for scrubbing and applying chemicals. Its strength and durability make it particularly suitable for applications where a more robust wipe is required.

The TX8949 wipe is not only strong but also resistant to a variety of solvents and acids. This resistance enhances its usability in semiconductor fabs, where compatibility with different cleaning agents is crucial. Whether it's tackling tough cleaning tasks or applying chemicals in a controlled manner, the Texwipe TX8949 Polyester Cleanroom Wiper stands out as a reliable choice in semiconductor manufacturing.

Texwipe's commitment to quality and innovation is evident in the diverse range of cleanroom wipes they offer. Texwipe continues to be a trusted partner in maintaining cleanliness and protection in semiconductor fabs.

Benefits of Using Cleanroom Wipes:

-

Particle Control: Cleanroom wipes are engineered to control and eliminate particles that can compromise semiconductor manufacturing processes. The low particle generation of wipes like the CapSure-VP and Texwipe polyester wipes ensures a clean and controlled environment.

-

Surface Compatibility: Semiconductor fabs house a variety of surfaces and materials. Cleanroom wipes are designed to be compatible with different surfaces, including sensitive materials used in semiconductor manufacturing. This ensures that the wipes effectively remove contaminants without causing damage.

-

Versatility: Cleanroom wipes are versatile tools that can be used for a range of cleaning applications within semiconductor fabs. From general surface cleaning to critical cleaning of sensitive components, these wipes offer a solution for various needs.

-

Consistency in Performance: The consistent performance of cleanroom wipes is crucial in semiconductor manufacturing, where precision and reliability are paramount. Wipes like the CapSure-VP and Texwipe polyester wipes undergo rigorous quality control measures to ensure consistent performance in every batch.

Conclusion

In the fast-paced and highly controlled environment of semiconductor fabs, cleanliness is not just a preference; it's a necessity. Cleanroom wipes, such as the CPSVP09098 Berkshire CapSure-VP Knitted SE Wiper and Texwipe polyester cleanroom wipes, play a pivotal role in elevating cleanliness and protection within these facilities. Their advanced design, particle control capabilities, and compatibility with sensitive surfaces make them indispensable tools in the pursuit of flawless semiconductor manufacturing. As technology continues to advance, the role of cleanroom wipes will only become more critical in ensuring the production of high-quality, defect-free semiconductors.

For over 40 years, Lab Pro Inc. is your steadfast source for premium cleanroom wipes, hand tools, lab equipment, chemicals, and PPE apparel. Trusted by aerospace industries, medical device companies, and laboratories globally, we epitomize exceptional quality in every product. Experience the convenience of next day service in California. Contact us online or at 888-452-2776 to explore solutions tailor-made for the laboratory industry. Elevate your experiments with Lab Pro Inc. – your partner in precision and excellence.