- No products in the cart.

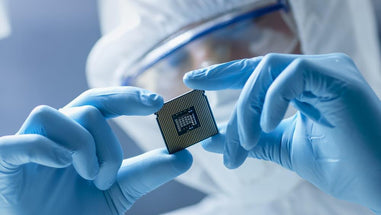

When working on an electronic production line, cleanliness is critical. It's essential to keep the work area and components free from contamination in order to ensure the final product meets quality standards.

Printed circuit boards (PCBs) are used in almost all electronics. During electronics assembly, surface mounted components are soldered to the board. A stencil is used to deposit solder paste at designated places on the board so that the components can be perfectly aligned.

Stencil cleaning is an important part of the process. By using the right wipe to clean stencils and remove excess solder and other contaminants, you can help ensure the final product is free from defects. This is becoming even more critical as electronic devices are getting smaller and there is even less margin for error.

Wipes are commonly used for cleaning circuit boards and stencils, but which type of wipe is best for the job?

Presaturated IPA wipes

IPA or isopropyl alcohol is a solvent that is very effective as a disinfectant and cleaning product. It's a standard cleaning solvent used in the electronics industry because it is low cost and effective at removing solder residue and many other contaminants.

A wipe that is presaturated with IPA is very convenient, allowing cleaning activities to be performed quickly and effectively without slowing down workflow.

Advantages of IPA for electronics cleaning:

- Low cost

- Good for cleaning most common contaminants - solder, inks, adhesive and polar oils

- Readily available

- Convenient to use

Disadvantages of IPA for electronics cleaning:

- Not so effective at removing nonpolar oils and grease

- Highly flammable

- Can cause skin and eye irritation (PPE required)

IPA wipes come presaturated with different concentrations of isopropyl alcohol solution. If you're looking for a wipe for production line electronics cleaning, you probably want one with a higher concentration of alcohol and minimal water content.

99-100% IPA Presaturated Wipes

These wipes have minimal water content, which is ideal when rapid evaporation is required. The cleaned area will quickly dry, allowing work to continue without delays.

The high IPA concentration means the wipe is very effective at dissolving a wide range of non-polar substances, meaning it is good for removing solder, oils, inks, and adhesives.

70-91% IPA presaturated wipes

Wipes with lower IPA concentrations may be slightly more economical, but the higher water content means a reduced drying time. This can slow down workflow, although the slower evaporation rate might be advantageous in some circumstances (e.g. when cleaning warm surfaces).

These wipes are still effective at cleaning and a 70% IPA wipe also has good disinfectant properties, which can be useful in some scenarios

Types of Wipes

In addition to choosing the best IPA concentration for your purposes, you also need to ensure that the wipe is made out of an appropriate material. When you're seeking a wipe for its cleaning properties, the last thing you want is a wipe that snags or leaves fibers, contaminating your work.

TechSpray Isopropyl Alcohol (IPA) Wipes – 99%

Made from a cellulose-poly material, these wipes have high absorbency, are lint-free and are unlikely to tear. They are also plastic-safe, making them ideal for PCB and stencil cleaning.

Advantages:

- Lint free

- Tear resistant

- Plastic safe

- Quick drying

Chemtronics IPA Presaturated Wipes - 91% IPA - SIP91P 100/tub

These wipes contain 91% pure IPA and 9% deionized water. They are strong, lint free, and plastic safe. They are ideal for the cleaning of printer stencils during and at the end of production runs.

Advantages:

- Strong material, resistant to tearing

- Lint free

- Available in dispensing box or pull through tub for convenience

IPA Spray and Dry Wipe

An alternative option to a presaturated wipe is to use a dry wipe with an IPA spray. This can be an economic way of purchasing your cleaning products, although it can be less convenient than a presaturated wipe.

Techspray 1610-PT - Technical Grade Isopropyl Alcohol (IPA) 99.8%

This is a pure anhydrous IPA which is ideal for stencil cleaning and other electronic production line work. It is available in a spray bottle and bulk containers.

You will then need to choose a suitable dry cloth to apply the IPA.

You will want to look for a durable, lint free cloth which leaves no fibers when used to clean stencils and PCBs. Options include polyester wipes and polycellulose wipes. Whichever option you choose, you need to ensure that it is suitable robust for your application

In Summary

99-100% IPA solution is an ideal solvent for cleaning components in an electronics production line. You can apply this in spray form with a dry wipe, but presaturated wipes will provide improved convenience and speed. Whichever type of wipe you choose, it is important to ensure it is robust enough for your application and lint free.

For over 40 years, Lab Pro Inc. has been committed to delivering the highest quality chemicals, ESD protection, laboratory and cleanroom supplies to medical device and electronic manufacturing laboratories worldwide. To learn more, visit the biggest Lab Supply showroom in California, or contact us online or at 888-452-2776.