- No products in the cart.

Introduction

The mechanical and thermal properties of pure nitinol are extremely sensitive to the Ni:Ti ratio. So it should not be surprising that the addition of a small amount of a third element will have an effect also. For this reason, controlled amounts of iron, niobium, copper, and other elements can be used as alloying elements for nitinol to tailor its properties for certain applications [1].

In particular, the addition of copper can cause a number of changes to nitinol, including changing its hardness, shape memory behavior, and superelastic durability. These will be discussed in detail below. It should be noted that, while copper has benefits in terms of mechanical properties, it can have a negative effect on the corrosion resistance of nitinol in some cases [2].

When Cu is added to nitinol, it generally takes the place of Ni, while the Ti content remains constant at around 50% [3].

Hardness

Adding copper to nitinol has been shown to increase its hardness, from roughly 221-235 Vickers units to 305-319 Vickers units. In these cases, 2.5-2.59 wt% copper was added as an alloying element before Ni-Ti sintering [4].

In any application where nitinol will be in mechanical contact with other solid materials, increasing the hardness of the nitinol part will increase its durability and lifetime, though it may do this at the expense of damaging surrounding structures.

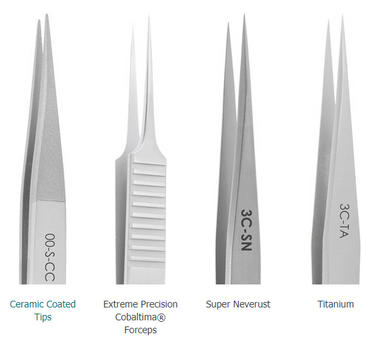

Even before adding copper, nitinol is a relatively hard material, with a hardness similar to steel. In fact, certain types of machining are avoided due to the hardness of nitinol [5]. Adding copper has the potential of increasing its hardness by roughly 30-40%. For this reason, specially designed cutters with sharp cutting edges made of hard materials are recommended for high quality, precise cuts of nitinol and copper-modified nitinol wires, tubes, and sheets [6]. These cutters should be cleaned and inspected regularly, and should be replaced if they become damaged or dull.

Phase Transition Temperature and Hysteresis

The key phenomenon behind the shape memory of nitinol is a transition between a high temperature (austenite) phase and a low temperature (martensite) phase. If a nitinol object is formed into a certain shape at high temperature, then cooled and deformed at low temperature, the object will “remember” and revert to its high temperature shape when it is heated.

The transition between the low and high temperature phase takes place at a different temperature when nitinol is being heated versus when it is being cooled. The difference in temperature, referred to as hysteresis (see Figure 1), can be in the range of 30 - 60 °C depending on the specific Ni:Ti ratio.

Figure 1: Schematic of hysteresis in the phase transformation between martensite and austenite in nitinol. From [7].

The addition of a small amount of copper can reduce the magnitude of this hysteresis, which is useful in applications where repeatable shape change of the nitinol part at a specific temperature is needed.

Copper also changes the temperature at which the shape memory transition occurs, which is important in applications which utilize the shape memory effect, for example orthodontic applications [8]. Depending on the amount of copper added, more complex changes in the shape memory behavior are possible, including the creation of two-step phase transformation for materials with Cu fractions of > 7% .Copper also has the effect of making the shape memory transition temperature less sensitive to Ni:Ti ratio, thereby widening the process window for manufacturing Nitinol [3].

Superelasticity Fatigue

Besides shape memory, the other important property of nitinol that makes it desirable for use in medical devices is its superelasticity, or ability to elastically (reversibly) deform more than most materials before the deformation becomes permanent. However, an issue with the use of nitinol in some applications is that it does not have the ability to elastically deform and recover an infinite number of times. Over the course of many cycles, both the transition temperature and the maximum superelastic deformation can drift, an effect called fatigue, leading to changes in thermomechanical behavior and possible failure.

Copper can be used to counteract this effect. It has been shown that adding copper at a level of 12-13 atomic % can increase the fatigue resistance of nitinol parts, up to the point of surviving 10 million repeat deformation cycles [9].

Yield Strength

Copper has the effect of reducing the yield strength (a measure of the force required to deform a material) of the low-temperature martensitic phase, while the yield strength of the high temperature austenitic phase is unchanged [3]. This can have advantages in working with nitinol parts at low temperature, but disadvantages in applications were high yield strength at low temperature is required.

Conclusions

The addition of copper to nitinol can be used to control its mechanical and thermal properties, including its hardness, shape memory, and superelastic durability. One potential drawback is that the corrosion resistance can also be affected. Because adding copper to nitinol increases its hardness, it becomes even more critical to have specially made, sharp cutting tools for copper-modified nitinol.

For over 40 years, Lab Pro has been committed to delivering the highest quality cutters and tweezers to tech laboratories worldwide. Come visit the biggest Lab Supply showroom in California, or contact us online or at 888-452-2776.