- No products in the cart.

Wire bonding is a cost-effective and versatile way to make connections to silicon-based integrated circuits. The technique involves bonding a wire, which can have a very small diameter, on the order of 10 microns, directly to a contact pad on the chip. Historically, aluminum and gold have been the most commonly used wire materials, but more recently, other materials like silver, copper, platinum, and a variety of alloys have also been used, driven mainly by cost, but also to match specific applications, for example to ensure that the wire bonding process fits into a safe window of conditions for the die [1]

Gold bonding wire’s shelf life

Manufacturers and users of gold bonding wire recommend a variety of maximum shelf lives after the wire is drawn, which fall in a range of roughly 3 to 12 months, with an average of 6 months [1,3,4,5], provided that the wire is stored under controlled temperature and humidity conditions (with recommended conditions generally normal indoor room temperature and < 65% relative humidity [5].

Gold is a convenient material for wire bonding because it is soft, malleable, and because its oxide does not affect the bonding process. Gold bonding wire has a finite shelf because, as it sits in ambient conditions, the wire can anneal, or undergo a rearrangement of its microcrystalline structure, causing it to lose these advantageous properties it developed during initial processing.

Gold wire can be alloyed with beryllium or calcium to improve bond quality and reliability. Metals that are more prone to form a stable oxide, like copper, must be stored and used under more stringent conditions. For example, copper wire bonding is typically conducted in a forming gas environment (95% N2 / 5% H2) [2].

The two key mechanical properties for a wire bonding material are elongation, which is the amount that the wire can be stretched without permanent (plastic) deformation, and breaking strength, the amount of load that the wire can support before breaking. Both of these parameters affect the design and performance of the wire bonding structure, and can be negatively affected by long shelf storage times.

After this time, it is advisable to dispose the wire and replace it with a fresh batch, since degraded wire can lead to incomplete or failed bonds, or weaknesses that could cause failures later, for example, breakage of the bonding wire during processing due to loss of hardness. Due to the expense of gold materials, it is best to take a systematic approach to tracking and re-stocking gold bonding wire.

This approach should include the following aspects:

-

A centralized inventory list updated in real time, which can then be used to track usage rate and when an item stock is low. For small- and medium-sized labs, a shared spreadsheet stored on a network drive works well for this.

-

A system for ensuring that stock is used using a LIFO (first-in-first-out) system. This is especially important for materials with limited shelf life.

-

Specific storage locations for commonly used materials- locations should be selected with ease of access, access control, and environmental conditions in mind

-

Assignment of a specific owner for tracking and reordering high value stock items

-

Partnering with a dedicated supplier who understands your needs and is ready with additional batches when needed.

The limited data available on the effect of shelf storage on gold bonding wire suggests that the breaking strength of as-manufactured wire decreases by roughly 5-15% in the first 1-2 months [1]. Intentional pre-annealing of the wire can reduce this change. Furthermore, wire bonding tool manufacturers cite wire shelf aging as a possible cause for wire breakage and poor bond formation [4].

It should be noted that copper wire, while a cheaper alternative, has a shorter shelf life and should be used within one week of initial exposure to air [6].

Additional gold bonding wire handling recommendations

Besides long shelf storage times, the following can also degrade the quality of gold bonding wire, leading to failures during assembly:

-

Improper handling of bonding wire can have serious consequences for the quality and reliability of the wire, far beyond the effect of shelf storage. For example, pressing a hard object on a spool of wire, creating a nick or dent, can cause any wire connections made with the damaged sections unreliable.

-

Environmental contamination, for example dirt and oil, can also lead to unreliable bonds. For this reason, and the bullet above, gold wire spools should be stored away from active work areas where they are prone to damage and contamination.

-

Contamination of tools or bond pads, worn tools, or too much heat [4]. Excessive heating can be an issue if it is enough for the wire to become annealed, changing its mechanical properties.

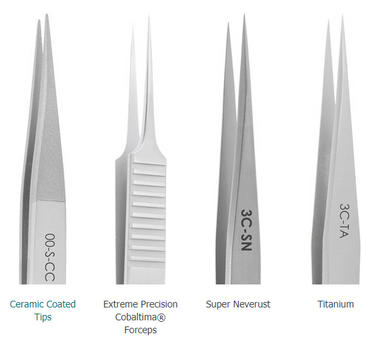

Use of bonding wire of any kind requires making clean wire cuts, often in tight spaces that cannot be easily accessed with wire cutters. Cutting tweezers, which are designed to be able to cleanly cut fine wires in tightly confined spaces, are a useful tool in the wire bonding process. To ensure precise handling and cutting, the tweezers should be clean and sharp, with no contamination or excessive wear on the cutting edges.

Conclusions

Gold is the leading choice for use in bonding wire for die attachment. However, it’s advantageous properties degrade during shelf storage, so it should be used within 6-12 months of receipt. For many labs, this requires implementing inventory control and tracking systems, as well as working with a trusted supplier.

For over 40 years, Lab Pro has been committed to delivering the highest quality cutters and cutting tweezers to tech laboratories worldwide. Come visit the biggest Lab Supply showroom in California, or contact us online or at 888-452-2776.

References

-

https://electroiq.com/2002/06/the-back-end-process-step-6-wire-bonding/

-

https://www.inrf.uci.edu/wordpress/wp-content/uploads/hesse-wire-bonding-technology.pdf

-

https://www.inseto.co.uk/downloads/microelectronic-materials/Technical%20Data%20Sheet%20for%20Gold%20Bonding%20Wire.pdf