- No products in the cart.

In the intricate world of microelectronics, precision is paramount. Wafer tweezers, with their specialized design and delicate features, play a crucial role in handling micro-sized components. In this comprehensive guide, we will delve into the techniques and tips for effectively using wafer tweezers, focusing on three common tip sizes: 4 tooth, 6 tooth, and 8 tooth. Elevate your skills in microelectronics as we explore the nuances of picking, placing, and preventing damage.

Understanding Wafer Tweezers

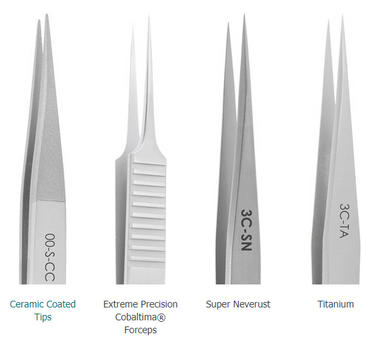

Before delving into specific techniques, let's understand the basics of wafer tweezers. These precision tools are designed with fine tips, allowing for the delicate handling of microelectronics components such as semiconductor wafers, integrated circuits, and other miniature parts. The choice of tip size can significantly impact the effectiveness and safety of handling these sensitive materials.

Tip Size Matters: 4 Tooth, 6 Tooth, and 8 Tooth

1. 4 Tooth Wafer Tweezers: Pinpoint Precision

Technique: Pinching and Lifting

- Use the 4 tooth wafer tweezers for pinpoint precision. The limited number of teeth ensures a focused grip on the microcomponent.

- Pinch the component gently between the tips and lift it with a steady motion.

- Ideal for handling smaller and more delicate microelectronic parts.

Tip: Angle Matters

- Adjust the angle of the tweezers to optimize grip and reduce the risk of slippage.

- Practice controlled movements to enhance accuracy, especially when placing components onto circuit boards.

2. 6 Tooth Wafer Tweezers: Balance of Grip and Stability

Technique: Controlled Squeezing

- The 6 tooth wafer tweezers offer a balanced grip, combining precision with a bit more stability.

- Use a controlled squeezing motion to secure the microcomponent between the teeth.

- Suitable for handling a range of microelectronic parts, striking a balance between delicacy and stability.

Tip: Practice Controlled Pressure

- Experiment with the pressure applied during squeezing to find the optimal grip for different components.

- Focus on maintaining a steady hand to avoid excessive pressure that might damage sensitive materials.

3. 8 Tooth Wafer Tweezers: Secure Handling for Larger Components

Technique: Gentle Clamping

- The 8 tooth wafer tweezers provide a secure grip, making them ideal for larger microelectronic parts.

- Use a gentle clamping motion to hold the component securely between the teeth.

- Suitable for handling integrated circuits and other more substantial microelectronics.

Tip: Stability during Placement

- Prioritize stability when placing larger components onto intricate circuitry.

- Employ a two-step motion – first, bring the component close to the target area, and then make fine adjustments for precise placement.

Mastering the Art of Wafer Tweezer Wielding: Essential Techniques and Tips

Now, let's equip you with the skills to wield your chosen tweezers like a microelectronics maestro:

- Preparation is key: Ensure your workspace is clean and well-lit. Wash your hands and keep them dry to avoid contamination.

- Grip like a pro: Hold the tweezers comfortably, close to the hinge for maximum control. Use your fingertips for fine movements and avoid squeezing the handles too tightly.

- Pick and place with precision: Gently approach the component from the side, align the tip, and apply even pressure to grasp it securely. Lift straight up and avoid excessive force.

- Positioning matters: Place components carefully, aligning them with the designated pads or slots. Use a gentle rocking motion to settle them into place.

- Soldering with finesse: When soldering, preheat the tip of the tweezer to avoid transferring heat shock to the component. Hold the component slightly away from the soldering point and avoid prolonged contact.

- Safety first: Be mindful of ESD risks. Use grounded tools and ESD-safe tweezers for sensitive components.

- Cleanliness is next to godliness: Regularly clean your tweezers with isopropyl alcohol and lint-free wipes to prevent contamination and maintain grip.

Conclusion: Elevate Your Precision in Microelectronics

Mastering the use of wafer tweezers in microelectronics demands a combination of technique, precision, and a deep understanding of the components you're handling. By embracing the nuances of different tip sizes and implementing best practices, you can elevate your skills and contribute to the flawless assembly of intricate microelectronic devices. Whether you're working with semiconductor wafers, integrated circuits, or other delicate components, the right techniques and tips will empower you to navigate the world of microelectronics with confidence and precision.

For over 40 years, Lab Pro Inc. has been committed to delivering the highest quality Excelta Wafer tweezers, lab supplies, lab equipment, reagents, distance learning kits, and cleanroom PPE apparel. Renowned by global medical device companies and laboratories, we ensure exceptional quality in every product. Contact us online or call 888-452-2776 to learn more. Discover top-notch lab supplies and elevate your experiments today!