- No products in the cart.

What is Medical Device Manufacturing?

Medical device manufacturing plays a key role in the healthcare system. That’s because it deals with medical products that diagnose, monitor, and treat conditions and diseases. Medical device manufacturing covers a wide selection of products ranging from common supplies for local family doctors to high-tech equipment for highly trained medical specialists.

Why Are Precision Tools Needed For The Medical Device Manufacturing Industry?

Precision tools are important to the medical device manufacturing industry because they are custom designed and manufactured with components that are unique, accurate, and designed specifically for certain procedures. The following are some common precision tools.

- Tweezers

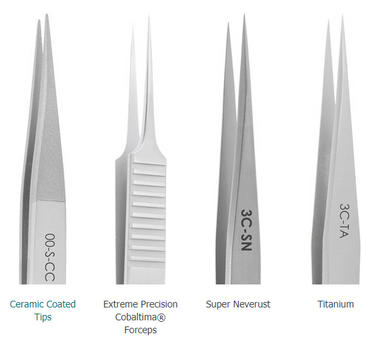

Tweezers are a hand tool that are designed to perform high precision tasks in the laboratory or during medical procedures. They are fine tipped instruments with pincers designed to grasp or extract. There are various types of tweezers designed for different high precision tasks.

Tweezers that are used for lab operations involving heat are ceramic tweezers, ergonomic tweezers, exotic metals tweezers, miniature tweezers, plastic tweezers, and reverse action tweezers.

Tweezers that can be used for a variety of lab operations include conventional style tweezers, general tweezers, and lab tweezers. The ultra precision cobaltima tweezers have ultra precision tips for high power microscopy. The small parts handling tweezers are for use in compact and hard to reach sections. Cutting tweezers are used to cut up soft wires.

- Cutters and Pliers

Cutters are another tool used and designed for precision cutting. Cutters have a handle grip and blades on the end. Cutters include general cutters, hard wire cutters, side cutters for gripping, cutting, and stripping wires, specialty cutters for working at an unusual angle, cutting component leads, handling medical tubings, and stand off shear cutters for connector pins and component leads.

Pliers can be used for straightening wires and making fine-tuned precision adjustments. Pliers are designed with a grip handle, spring, and various tips for specific procedures such as adjusting the center dimensions of radial lead components, and removing small pieces of tissue and bone. Pliers include transistor forming, forming J hooks, roll pin insertion and extraction, flat nose pliers, rongeurs, small chain pliers, needle nose pliers, large bent pliers, cut & form dog leg pliers.

- Scissors and Instruments

Scissors are used for cutting and dissecting in the lab. They are designed with two finger rings and blades on the end. Scissors include straight, curved, slim blade, shear cut, trimmer, sharp point, and blunt point. Scissors vary according to their length and type of blade.

- Probes and Spatulas

Probes are slender long instruments with tips that are used for exploring. Probes are used to handle tissue during surgery and to identify nodes and other biological matter. Probes include needle probes and temperature probes with straight tips, angled tips, hooked tips, micro tips, and double ended.

Spatulas are used for scraping, mixing, and transferring samples from one location to another. They are designed with a handle and various ends such as a flat end or an end for scooping. Spatulas include micro scoop, mini, and double-ended. Some are made with a soft grip, with a spoon, wooden handles, and out of stainless steel.

- Scalpels and Blades

Scalpels are used to dissect samples. They are great for slicing and scraping in tight areas. Scalpels are designed like a knife with a small sharp blade. They come with straight blades, angled blades, curved blades, and some of the blades are reusable or disposable.

- Swabs

Swabs are used for precision cleaning or for the collection of specimens from areas that are hard to reach. They are usually designed with soft material on the end of a stick. Swabs include cotton tip swabs, ESD safe swabs (electrostatic discharges), foam tip swabs, and polyester tip swabs.

- Visual Inspection Products

Visual inspection products are designed for the visual inspection of hard-to-reach areas or areas that don’t fall within the field of vision. This typically includes the process of material handling, emergency medical services, and thermal imaging.

Precision tools such as tweezers, cutters, pliers, scissors, probes, spatulas, scalpels, swabs, and visual inspection products are all crucial to the medical device manufacturing industry. These tools have a specific set of design requirements to perform precision tasks in the medical field. Their components are designed to be safe, accurate, and reliable.

When precision tools are being manufactured, they must meet federal and international regulations. These precision tools are designed to provide the best level of care to patients.

Lab Pro offers a large variety of medical device manufacturing tools. For over 40 years, Lab Pro Inc. has been committed to delivering the highest quality chemicals, lab equipment, distance learning kits, lab supplies, and cleanroom PPE apparel to medical device companies and laboratories worldwide. To learn more, visit the biggest Lab Supply showroom in California, or contact us online or at 888-452-2776.