- No products in the cart.

Nitinol wire is made of an alloy of nickel and titanium, which has unique mechanical properties that make it attractive for use in a number of nitinol wire applications. There has been an explosion of growth of Nitinol in the past decade mostly due to Health Care providers and patients who have welcomed the transition from traditional open-surgical procedures, which require long hospital stays, to minimally invasive techniques. As surgeons create better techniques, older types of procedures become less common, including many open procedures. This demand for less-invasive procedures has allowed novel instrumentation and implants to be designed. An increasing number of these medical devices use Nitinol as the critical component. This article will focus on key attributes of Nitinol that make it an ideal material for medical applications. Let's explore the two most important of these properties , superelasticity and shape memory.

Applications:

Stents

Both the superelastic and shape memory properties of nitinol can be used in stent applications [1,6]. For example, a stent which is above its transition temperature (“superelastic”) can be compressed into a small diameter catheter, placed in the desired location, then released from the catheter to expand to its desired shape reversibly. The shape memory effect can also be used in this type of procedure, if the stent can be cooled below its transition temperature before introduction, then warmed by the body to above its transition temperature, expanding into its desired shape.

Unlike balloon-expanded stents, nitinol stents will expand to exactly their pre-set size when released into the vessel, without recoil, eliminating the need for over-expansion after placement.

For similar reasons, nitinol is used in embolization, thrombolysis, and other similar interventional procedures.

Niinol Wire

Catheter guide wires

This is a second well-established application for nitinol wires, having been used for this application for over 30 years. The advantages to using nitinol as a guide wire material is its kink resistance, and minimum bending radius, which is roughly ten times smaller than stainless steel [1,5]. This property allows nitinol guide wires to be used to navigate highly tortuous pathways.

Snares and baskets

Nitinol can be used to form loop snares which can be used to retrieve foreign bodies from vessels. In this case, the wire can be over-wrapped with a material with higher radioopacity, such as gold-plated tungsten, for visualization during the procedure [7].

Similarly, it can be used to form expandable baskets for use in retrieving stones and other foreign bodies via endoscopic methods [8, 9].

Orthodontia

Nitinol applies a relatively constant level of stress over a range of tensile strain. In other words, the restoring force is relatively constant at a wide range of deformations, similar to bone. So when used in orthodontic applications, nitinol wires will apply a relatively constant force to teeth as they move, and so they require less frequent tightening compared to stainless steel wire [10].

Orthopedic fracture fixing

For similar reasons, nitinol can be have advantages in bone fixturing devices compared to titanium and stainless steel. Besides its shape memory and superelastic properties, it has an elastic modulus that is similar to natural bone, which reduces stresses when mechanical loads are shared between bone and the implant.

Anastomosis

A significant fraction of complications in bowel surgery come from the use of sutures or staples to reconnect loops of bowel. Using a nitinol ring to compress sections of bowel together is an alternative approach, and can be done in a way that leads to the excretion of the nitinol compression ring when the reconnection process is completed.

Nitinol Properties:

Shape Memory: When nitinol is formed into a shape at an elevated temperature, it will always return to that shape when heated above a certain transition temperature, even if the shape is deformed at lower temperature. An example of this is a nitinol stent, which can be formed at a high temperature, then cooled and folded into a compact shape for easier insertion into a vessel. When heated above the transition temperature, the stent will re-expand into the desired shape and apply pressure to the walls of the vessel. The temperature at which the transition takes place can be precisely controlled by varying the nickel to titanium ratio in the material.

Superelasticity: Nitinol has the ability to elastically recover from a much higher degree of deformation compared to other metals. Stainless steels, for example, can recover after being deformed by roughly 1% before the deformation becomes irreversible, while nitinol can recover from deformations of 10% or more. Nitinol has this property only above its shape memory transition temperature.

Nitinol compositions are sometimes classified as either “shape memory” or “superelastic”. However, all compositions exhibit both properties. These classifications refer to whether the particular nitinol composition has a transition temperature which is above a certain reference temperature (in which case it is referred to as “shape memory”) or below the reference temperature (“superelastic”). For biomedical applications, the average human body temperature of 37 °C is commonly used as the reference temperature.

In some applications, for example in orthodontic arch wires and orthopedic implants as discussed below, another useful property is that it exerts a relatively constant force over a range of deformation. It is also kink-resistant, unlike stainless steel [1]. This is of particular importance for use in guide wire applications, or for stents used in peripheral locations where bending or crushing of the stent is possible.

In addition to these unique material properties, nitinol has comparable biocompatibility relative to other implant materials, especially when it is pre-treated using electropolishing or other passivation techniques [2]. The biocompatibility of nitinol is believed to be due to a layer of highly nonreactive TiO2 that forms on the surface during passivation, preventing the leaching of nickel. Like other implant materials, the biocompatibility of nitinol is dependent on its environment. Because of this, in April 2019 the FDA issued draft recommendations that the biocompatibility of nitinol-containing medical devices should be tested in environments representative of where they would be used in the body [3].

Nitinol does have drawbacks that affect some applications. For one, it is difficult to weld to other materials. However, its intrinsic elasticity and shape memory properties can be used to join it, when parts are specifically designed for this purpose [4]. It has a radio-opacity similar to stainless steel, so if a higher degree of radio-opacity is needed, other materials must be incorporated into the construction [5].

Excelta 7241E Wire Cutter

Cutting Nitinol wire

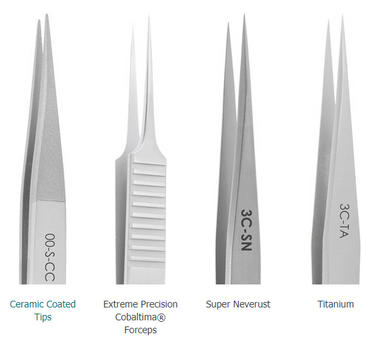

Nitinol wire is relatively hard (Rockwell hardness of ~ 60, similar to tool steel), and often in fine wire form. For these reasons, specially designed cutters and cutting tweezers with sharp cutting edges made of hard materials are recommended for high quality, precise cuts.

SUMMARY

In the past 10 years, Nitinol has earned prominent position in biomedical applications specifically minimally invasive surgeries and we can only expect the use of it in medicine to increase. As processing capabilities improve, instruments and devices such as stents, catheter tubes, snares, among others, will make more and more use of its unique mechanical properties. Nitinol has definitely found a home in the medical industry for years to come.

For over 40 years, Lab Pro has been committed to delivering the highest quality cutters and tweezers to medical device and biomedical laboratories worldwide. Come visit the biggest Lab Supply showroom in California, or contact us online or at 888-452-2776.

References:

-

https://pdfs.semanticscholar.org/b5c6/56cd08b084d101cdb21a84aa56486981944e.pdf

-

https://matthey.com/-/media/files/articles/mdb-oct-2015-nitinol.pdf

-

http://www.bostonscientific.com/content/gwc/en-US/products/retrieval-devices/optiflex.html

-

https://www.nordsonmedical.com/Components-and-Technologies/Nitinol-Components/