- No products in the cart.

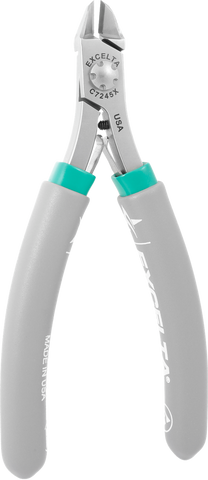

Excelta carbide cutters are renowned for their quality and performance in precision cutting applications. Whether you are working with electronics, jewelry, or other delicate materials, maximizing efficiency with Excelta carbide cutters is crucial for achieving clean and precise cuts. In this blog post, we will explore valuable tips and techniques that can help you enhance your cutting process, improve productivity, and ensure optimal results with Excelta carbide cutters.

Understanding Excelta Carbide Cutters

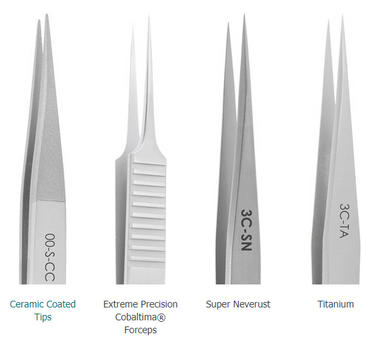

Excelta carbide cutters are crafted with high-quality tungsten carbide blades, known for their exceptional hardness and durability. The sharp cutting edges and robust construction of these cutters make them ideal for applications that require precision and clean cuts, such as in electronics assembly, jewelry making, and fine instrument manufacturing.

Tip 1: Choose the Right Cutter for the Job

Excelta offers a variety of carbide cutters, each designed for specific cutting tasks. When selecting a cutter, consider the type of material you will be working with and the specific cutting requirements. Different cutters may have varying blade profiles, such as flush cut, semi-flush cut, or pointed tip, which can optimize cutting performance for different applications. Choosing the right cutter for the job ensures maximum efficiency and reduces the risk of damaging the material or the cutter itself.

Tip 2: Maintain Proper Blade Alignment

Proper blade alignment is critical for effective cutting. Ensure that the cutting edges of the carbide blades are aligned and in contact throughout the cutting motion. Misalignment can lead to uneven or incomplete cuts, causing additional stress on the blades and reducing the overall efficiency of the cutting process. Regularly inspect and adjust the blade alignment to maintain optimal performance.

Tip 3: Apply Adequate Cutting Pressure

Applying the right amount of cutting pressure is essential for achieving clean cuts without causing unnecessary strain on the cutter or the material. Avoid excessive force, as it can lead to premature blade wear or damage. Let the sharpness of the carbide blades do the work, applying gentle and controlled pressure to achieve optimal cutting results. Experiment with different pressure levels to find the sweet spot for each material and cutting application.

Tip 4: Use Precision Cutting Techniques

Employing precision cutting techniques can significantly enhance the efficiency of your cutting process. Consider these techniques:

- Cut at the Appropriate Angle: Position the cutter at the correct angle to the material to achieve clean and precise cuts. Experiment with different angles to find the most effective approach for each cutting application.

- Cut in One Smooth Motion: Avoid multiple cutting attempts or sawing motions, as they can lead to jagged cuts or damage the material. Instead, make a single, continuous cutting motion for clean and consistent results.

- Support the Material: Use appropriate supports or fixtures to stabilize the material being cut. This minimizes vibrations and movement, ensuring better control and accuracy during the cutting process.

Tip 5: Regular Maintenance and Blade Care

Maintaining Excelta carbide cutters is essential for their long-term performance and efficiency. Regularly clean the blades to remove any debris or residue that may affect cutting performance. Keep the blades sharp by using appropriate sharpening tools or consulting the manufacturer's guidelines. Dull blades can lead to inefficient cutting and may require additional force, increasing the risk of damage to the cutter or the material.

Conclusion

By implementing these tips and techniques, you can maximize efficiency and achieve clean, precise cuts with Excelta carbide cutters. Choosing the right cutter for the job, maintaining proper blade alignment, applying adequate cutting pressure, utilizing precision cutting techniques, and regularly maintaining and caring for the blades are all crucial steps in optimizing cutting performance.

Excelta carbide cutters are trusted tools known for their quality and durability. When used correctly and with the right techniques, they can greatly enhance productivity and deliver exceptional results in various applications, including electronics assembly, jewelry making, and fine instrument manufacturing.

Investing in high-quality tools and employing proper cutting techniques not only improves efficiency but also extends the lifespan of your carbide cutters. Regular maintenance, cleaning, and blade care are essential to ensure long-term performance and optimal cutting results.

For over 40 years, Lab Pro Inc. has been committed to delivering the highest quality nitinol cutting tools such as Excelta carbide insert cutters, lab supplies, lab equipment, reagents, distance learning kits, and cleanroom PPE apparel. Renowned by global medical device companies and laboratories, we ensure exceptional quality in every product. Contact us online or call 888-452-2776 to learn more. Discover top-notch lab supplies and elevate your experiments today!