- No products in the cart.

Nitinol, a shape memory alloy composed of nickel and titanium, is widely used in various industries for its unique properties. Cutting Nitinol wires requires specialized techniques to achieve clean, precise cuts without compromising the integrity of the material. In this blog post, we will delve into the essential techniques and best practices for mastering the art of cutting Nitinol wires. By following these guidelines, you can achieve optimal results and maintain the mechanical properties of the material.

Understanding Nitinol

Before diving into cutting techniques, it is crucial to understand the characteristics of Nitinol. Nitinol wires possess shape memory and superelasticity, which means they can return to their original shape after deformation and exhibit high flexibility. However, Nitinol is a challenging material to cut due to its high hardness and resilience.

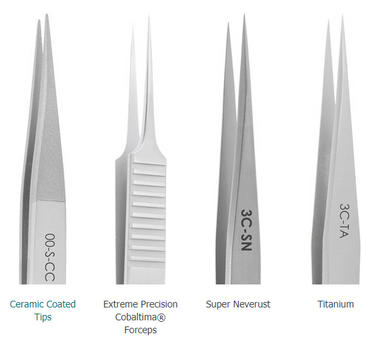

Selecting the Right Tools

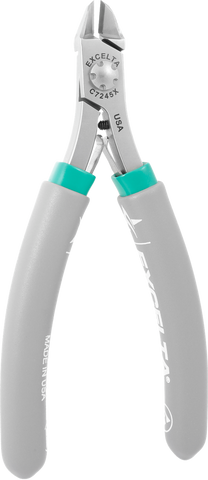

To achieve precise cuts in Nitinol wires, it is vital to choose the right cutting tools. Carbide cutters are highly recommended due to their hardness, durability, and resistance to wear. Excelta carbide cutters, for instance, are renowned for their quality and performance. They provide excellent cutting capabilities and are suitable for handling Nitinol wires.

Best Practices for Cutting Nitinol Wires

-

Use Proper Technique: When cutting Nitinol wires, use a slow, steady cutting motion. Avoid applying excessive force, as it can cause deformation or create burrs. Let the cutter do the work and guide it smoothly through the wire.

-

Support the Wire: Nitinol wires should be adequately supported during the cutting process to prevent excessive vibration or movement. Use a vise or clamps to secure the wire in place, ensuring stability and accuracy during cutting.

-

Lubrication: Applying a small amount of lubricant, such as cutting oil, can help reduce friction and heat generated during cutting. This lubrication helps maintain the integrity of the Nitinol wire and prolongs the life of the cutting tool.

-

Wear Safety Gear: When working with Nitinol wires, always wear appropriate safety gear, including safety glasses and gloves. These precautions protect against potential wire fragments or burrs that may be produced during the cutting process.

-

Avoid Excessive Heat: Nitinol is sensitive to heat, which can affect its properties. To prevent overheating, limit the duration of the cutting process and take breaks to allow the wire and cutting tool to cool down if necessary.

-

Post-Cutting Treatment: After cutting Nitinol wires, inspect the cut ends for any deformities, burrs, or sharp edges. Smooth any rough surfaces or burrs using fine-grit sandpaper or a deburring tool to ensure the wire is safe to handle.

-

Quality Assurance: Conduct periodic quality checks to verify the precision and accuracy of the cut Nitinol wires. Measurements should meet the required specifications, and visual inspections should confirm clean, smooth cuts.

Conclusion

Cutting Nitinol wires requires a delicate balance of technique, tools, and best practices to achieve clean, precise cuts without compromising the properties of the material. By selecting the right cutting tools, such as Excelta carbide cutters, and following essential techniques, such as proper support, lubrication, and safety precautions, you can master the art of cutting Nitinol wires. Always remember to be mindful of Nitinol's characteristics, avoid excessive heat, and conduct post-cutting treatments to ensure optimal results. With practice and attention to detail, you can achieve accurate cuts that maintain the integrity and functionality of Nitinol wires in various applications.

For over 40 years, Lab Pro Inc. has been committed to delivering the highest quality nitinol cutting tools such as Excelta carbide insert cutters, lab supplies, lab equipment, reagents, distance learning kits, and cleanroom PPE apparel. Renowned by global medical device companies and laboratories, we ensure exceptional quality in every product. Contact us online or call 888-452-2776 to learn more. Discover top-notch lab supplies and elevate your experiments today!