- No products in the cart.

Many electronic components utilize magnetic fields as part of their intended mode of function. But, when it comes to the mechanical manipulation of these components for experimental or manufacturing purposes, magnetism is a major obstacle. Rather than being able to use a laboratory technician’s fine motor skill to seamlessly alter electronic components, magnetic fields ensure that any ferromagnetic tools will wobble or twist when the operator needs stillness for precision. This means that for laboratories which routinely conduct work in a high-magnetism environment, anti-magnetic tweezers are essential tools.

The beneficial features of anti-magnetic tweezers may not be obvious to laboratory staff who aren’t familiar with their properties, however. While anti-magnetic materials are generally useful for a handful of purposes, in the context of an electronics laboratory, tweezers which do not respond to magnetic fields are uniquely useful because they can handle components more precisely and more consistently than ferromagnetic tweezers. Similarly, anti-magnetic tweezers can stay in the operator’s hand rather than becoming stuck to a magnetized surface. Each of these properties implies a more efficient and easier working experience for lab staff.

Higher Precision

When a strong magnetic field is perturbing the position of the prongs of a tweezer, it can be extremely difficult to perform the high-precision manipulations necessary for electronics assembly or jewelry making. While it might be physically possible for a technician to compensate for the perturbance of the magnetic field on their tweezer prongs with an abundance of effort if the magnetic field is weak enough and predictable enough, like in a bar magnet, most managers and staff prefer an easier solution which is less reliant on fine motor control.

Furthermore, in the case of magnetic fields with substantial heterogeneity in each of the three spatial dimensions, like the magnetic field produced by a solenoid, even the most meticulous operators will struggle to compensate for the forces exerted. Anti-magnetic tweezers are thus the preferable option, as the anti-magnetic tweezer prongs will not be influenced by the magnetic field of an electronic component.

As a result, anti-magnetic tweezers will make working with the following magnetic-field-producing components significantly easier:

- Wire loops

- Bar magnets

- Solenoids

- High-voltage wires

Subsequently, when a technician attempts to perform a delicate operation on an electronic component which is near a magnetic field, they’ll be able to do so more rapidly and more accurately than they could otherwise. The stronger and more contoured the magnetic field in question, the greater the value of the anti-magnetic tweezer set. For a component nestled near a powerful magnet with an irregularly shaped magnetic field, it’s difficult to imagine getting much work done with anything other than an anti-magnetic tweezer.

Pictured: Operator working with anti-magnetic tweezers at a workstation

Non-Stick Action

When working with ferromagnetic tweezers in the presence of a moderately strong magnet, it’s easy to understand why the tweezer prongs would be attracted to one of the poles of the magnet. But, when working in the presence of an exceptionally powerful magnet, like in an MRI machine, perturbation of the tweezer prongs by the magnetic field is less of a concern than the prongs of the tweezer sticking to the magnet and becoming permanently stuck. While most laboratories don’t routinely work with magnets of such great strength, for those that do, the risk of a pair of tweezers becoming powerfully glued to the magnet demands an investment in anti-magnetic tweezers.

The problem of tools sticking to a powerful magnet becomes more and more prominent the more powerful the magnet is, especially when the magnet in question is ferromagnetic rather than electromagnetic. While it might be possible to simply turn off the power to an electromagnet after a tool becomes stuck, with a powerful ferromagnetic material, there is no such recourse.

When tools become stuck to the strongest ferromagnets, it may be physically impossible to pry them apart, causing the magnet to be harder to use in the future and the tool to be effectively lost. Even worse, objects stuck to powerful ferromagnets may cause the magnet to chip or corrode depending on the force of impact and the materials of the stuck object.

Given that magnets become weaker when exposed to strong mechanical forces like the strike of a magnetized pair of tweezers, the magnet itself may be rendered useless or unsuitable for precision purposes as a result of the distortion to its magnetic field. In some cases, the entire device may be rendered inoperable as a result of a stuck ferromagnetic tool. Using anti-magnetic tweezers heads off the possibility of experiencing any of these problems in the lab.

Consistency of Handling

When working with electromagnets in both their powered and unpowered states, anti-magnetic tweezers are favorable because they will behave the same in both of the magnet’s states. Whereas a normal set of tweezers would be influenced by the magnetic field exerted by the electromagnet when electricity is flowing, they would behave normally when the magnetic field was deactivated.

This means that if technicians were expected to work on components near the electromagnet in both of its power conditions, their tool would handle differently depending on whether the electromagnet was powered or unpowered, making it difficult to utilize their muscle memory properly for their work.

With an anti-magnetic set of tweezers, it makes little difference whether the electromagnet is powered or not because the tweezers will handle the same way in both states, allowing the operator to manipulate components without any additional obstacles to precision. While this property of anti-magnetic tweezers is only relevant to a small handful of laboratories, for labs which routinely work on electromagnets, technicians will likely perform better when they don’t need to adjust their fine motor control depending on whether the magnet is switched on or off.

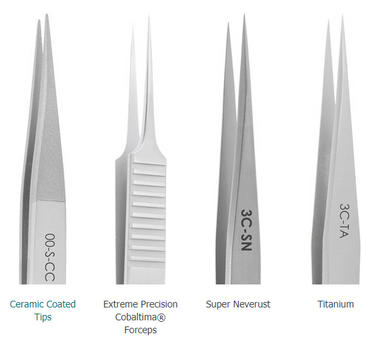

But which pair of anti-magnetic tweezers is the right choice for a given laboratory? Answering this question requires working closely with a laboratory tools supplier who understands the nuances of tweezer models and the spectrum of anti-magnetic metals which can be cast into precision tweezers. When labs work with suppliers that are familiar with the challenging aspects of their research or manufacturing environment, lab staff can rest assured that they’ll get the right tool for the job within the timetable that they need it.

For over 40 years, Lab Pro has been committed to providing electronics manufacturing supplies like anti-magnetic tweezers in California and worldwide. Come visit the biggest Lab Supply showroom in California, or contact us online or at 888-452-2776.