- No products in the cart.

Menu

Start typing to see products you are looking for.

Start typing to see products you are looking for.

Browse Categories

-

PPE Apparel

Masks

-

KN95 Respirator Mask, 4 layers, Box of 50 -LP-KN95-001BOX50

$79.00

KN95 Respirator Mask, 4 layers, Box of 50 -LP-KN95-001BOX50

$79.00

-

Harley N95 NIOSH Certified Particulate Respirator Mask, Folder Style 20/Box - L-188

$36.00

Harley N95 NIOSH Certified Particulate Respirator Mask, Folder Style 20/Box - L-188

$36.00

-

Lab Pro Mask KN95 (K-N95) Pack of 50 - LP-MASK2-K95 - 40% OFF

Lab Pro Mask KN95 (K-N95) Pack of 50 - LP-MASK2-K95 - 40% OFF

$125.00$75.00 -

Lab Pro 3ply Earloop Disposable Mask (Non-Surgical) (Box of 50) - 84% OFF

Lab Pro 3ply Earloop Disposable Mask (Non-Surgical) (Box of 50) - 84% OFF

$57.00$9.00

-

-

Chemicals

-

Wipes

-

Microscopes and Lighting

-

Hand Tools

Hand Tools

-

Gloves

-

Swabs and Applicators

Foam Tipped Swabs

-

ESD & Static Control

ESD & Static Control

-

Lab Equipment

-

Pipettes

-

Furnaces and Ovens

Furnaces and ovens

-

All Products

- Services New

-

Industries Served

- Brands

- Promotions

-

Information

-

Blog

-

All blogs

- Aerospace

- Calibration of Lab Equipment

- Chemicals and Solvents

- Cleanroom and Critical Environment

- Electric Battery Labs

- ESD Safety

- Lab Consumables

- Lab Glassware and Glassware Equipment

- Lab Pro’s Top 5

- Laboratory Equipment

- Laboratory Safety & Lab Efficiency

- Medical Adhesives

- Medical Device Industry

- Microscopes, Lighting & Inspection

- News

- Our Blog

- Pipettes

- PPE and Safety Apparel

- Press Release

- Science Education

- Solar Energy Labs

- Sustainable & Eco-Conscious Lab

- Swabs

- Tweezers and Cutters

- Ultrasonic Cleaning

- VMI for Lab Supplies

-

All blogs

- Contact

- All Categories

- Hand Tools

- Pliers

- Hakko CHP PN-2001 Pointed Nose Pliers - PN-2001

Hakko CHP PN-2001 Pointed Nose Pliers - PN-2001

$12.37

SKU: PN-2001

Warning:

California prop 65

Categories:

HAKKO

,Hand Tools

,Pliers

Description

SHOW MORE

Description

Description

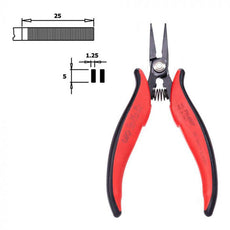

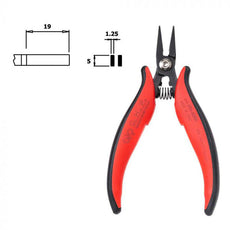

- Key Performance Benefit: The Hakko CHP PN-2001 is a precision tool for handling small components, offering excellent grip and control with its pointed, serrated jaws. Ideal for use in electronics assembly, hobby work, and general repair tasks.

- Material & Construction: These pliers are crafted from heat-treated steel to ensure long-lasting performance, while the serrated jaws provide a strong grip on delicate or small parts. The pointed nose allows for precise manipulation, even in tight or hard-to-reach spaces.

- Risk Reduction/Compliance Benefit: The ergonomic handle design reduces hand fatigue during extended use, ensuring comfort and safety when handling small components.

- Protection Level: The Hakko CHP PN-2001 pliers are designed for precision work, making them an essential tool for electronics repair, assembly, and small-part manipulation, while maintaining a safe, secure grip.

- Comfort & Usability: These pliers feature molded ergonomic handles grip and reduce hand strain during detailed work, making them ideal for both professional technicians and hobbyists.

- Safety & Compliance Assurance: Manufactured with high-quality materials and precise engineering to ensure safety during use in sensitive environments like electronics and precision assembly.

Recommended For

- Electronics assembly and repair

- Small parts handling in confined spaces

- Precision work on wires, components, and circuit boards

- General hobby or craft tasks requiring a fine grip

- Maintenance tasks involving small or delicate parts

Product Details

- Product Type: Pointed Nose Pliers

- Jaw Type: Serrated for enhanced grip

- Overall Length: 5.75 in (~146 mm)

- Jaw Length: 20 mm

- Tip Width: 1.2 mm (narrow pointed tip)

- Material: Heat-treated steel

- Handle: Molded ergonomic grips

- Applications: Electronics work, small part manipulation, precision tasks

Primary Industries

- Electronics

- Manufacturing & Repair

- Hobby & Craft

- Maintenance

Standards and Certifications

- Precision Tool Manufacturing

- General Compliance for Hand Tools

- ISO Standards for Quality

FAQs

How do pointed nose pliers improve precision in tight assemblies?

Pointed-nose pliers allow users to access narrow gaps and densely populated assemblies that larger tools cannot reach. Their slim profile enables accurate positioning, bending, and holding of small components, reducing accidental contact with surrounding parts during delicate electronics or repair work.

When are serrated jaws preferred over smooth jaws?

Serrated jaws are useful when a secure grip is needed on small or slippery components. They help prevent parts from slipping during handling or positioning, which is especially helpful in repetitive assembly tasks where stability and control directly impact efficiency and overall work quality.

What factors should be considered before using these pliers on sensitive components?

Users should evaluate the component's fragility and surface finish. Applying controlled pressure and positioning the jaws carefully helps prevent marring or deformation, particularly when working with soft metals or precision parts in electronics and detailed assemblies.

How do ergonomic handles affect long-duration tasks?

Ergonomic handles help distribute hand pressure more evenly, reducing strain during extended or repetitive use. This can improve overall control and comfort, especially in professional environments where technicians perform detailed tasks for long periods and consistent hand stability is important.

What maintenance practices help extend the life of precision pliers?

Keeping the jaws clean and free of debris supports consistent gripping performance. Avoiding exposure to corrosive materials and storing the tool in a dry environment helps maintain alignment and surface condition, ensuring reliable operation and extending the usable lifespan of the pliers.