- No products in the cart.

In the world of medical technology, innovation is the driving force behind improved patient outcomes and more efficient procedures. One such innovation that has been making waves in recent years is Nitinol, a shape memory alloy that has revolutionized the medical field. Nitinol's unique properties make it an invaluable material for a wide range of medical devices and applications. In this blog post, we will explore what Nitinol is, its remarkable characteristics, and how it is transforming the landscape of medical treatment.

What is Nitinol?

Nitinol is a nickel-titanium alloy with the remarkable ability to "remember" its original shape and return to it when subjected to certain stimuli, such as heat or stress. This property is known as shape memory, and it has made Nitinol a game-changer in the medical field. The name "Nitinol" is a portmanteau of its two primary components: Nickel (Ni) and Titanium (Ti), along with the Naval Ordnance Laboratory where it was discovered in the 1960s.

Shape Memory: The Key to Innovation

Nitinol's shape memory property has opened up a world of possibilities in medical device design. When this alloy is deformed into a specific shape at a lower temperature, it can later "remember" and revert to its original shape when exposed to body heat. This unique characteristic has led to the development of a wide range of medical devices and applications that were once considered impossible or highly challenging.

Nitinol in Stents

One of the most well-known uses of Nitinol in the medical field is in the creation of stents. Stents are tiny, expandable tubes used to open blocked or narrowed blood vessels. Traditional stents were often made of stainless steel, which could cause complications due to its rigid nature. Nitinol stents, on the other hand, are incredibly flexible in their compressed state, allowing for easier insertion into the body. Once in place, they expand to their original shape, providing support to the blood vessel. This flexibility reduces the risk of complications and improves patient comfort during and after the procedure.

Orthopedic Applications

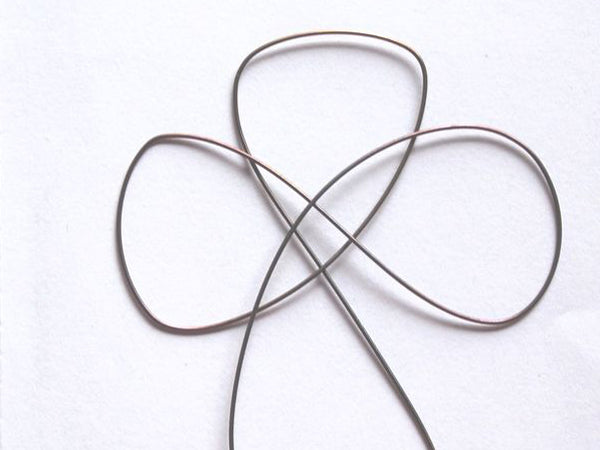

In orthopedics, Nitinol is being used to create innovative devices for various conditions. One notable application is in the development of orthodontic wires. These wires, used in braces, can exert a gentle, continuous force on teeth to move them into the desired position. Nitinol wires are ideal for this purpose because they can maintain a constant pressure while being biocompatible and resistant to corrosion.

Additionally, Nitinol is utilized in orthopedic implants, such as bone plates and screws. These implants provide stability and support for fractured bones. The shape memory property of Nitinol allows these implants to conform to the unique anatomical features of each patient, leading to better outcomes and reduced complications.

Minimally Invasive Surgery

The field of minimally invasive surgery has greatly benefited from Nitinol's unique characteristics. Surgical instruments and devices made from Nitinol can be designed to be incredibly small in their compressed state, making them easier to insert through small incisions. Once inside the body, these instruments can expand and perform various functions, such as cutting, cauterizing, or capturing tissue samples. This minimizes trauma to the patient, reduces the risk of infection, and speeds up recovery times.

Nitinol's Future in Medicine

As technology continues to advance, we can expect Nitinol to play an even larger role in the medical field. Researchers are exploring new ways to harness its shape memory properties for applications such as drug delivery systems, artificial muscles, and even smart implants that can adapt to changing conditions within the body.

Moreover, Nitinol's biocompatibility and resistance to corrosion make it a promising candidate for long-term implantation in the human body. Researchers are working on developing Nitinol-based devices that can monitor and treat chronic medical conditions, offering patients a higher quality of life.

Cutting Nitinol with Excelta Carbide Cutters

Cutting Nitinol requires precision and specialized tools, as this shape memory alloy is known for its resilience and ability to return to its original shape when subjected to stress. To cut Nitinol effectively, you can use carbide cutters from reputable brands like Excelta. These cutters are specifically designed for cutting tough materials like Nitinol and are available in various shapes and sizes to suit different applications.

To cut Nitinol with Excelta carbide cutters, follow these steps:

-

Safety First: Before you begin, make sure you are wearing appropriate safety gear, including safety glasses and gloves, to protect yourself from any flying metal fragments.

-

Select the Right Cutter: Ensure you have the correct Excelta carbide cutter for the job. The choice of cutter depends on the thickness and size of the Nitinol material you need to cut. Excelta offers a range of cutters with different cutting edge shapes and angles to suit various applications.

-

Secure the Nitinol: Properly secure the Nitinol material you intend to cut. Depending on the size and shape of the Nitinol piece, you may need a vise or clamps to hold it firmly in place. This is essential to prevent any unwanted movement during the cutting process.

-

Position the Cutter: Position the Excelta carbide cutter at the desired location for the cut. Ensure that the cutter's cutting edge is aligned with the line you want to cut along.

-

Apply Steady Pressure: Carbide cutters are known for their durability, but it's essential not to rush the cutting process. Apply steady and even pressure to the cutter while maintaining a controlled motion. Avoid sudden jerks or excessive force, as this can damage both the cutter and the Nitinol.

-

Lubrication: Depending on the thickness of the Nitinol and the type of Excelta carbide cutter you're using, you may benefit from using a cutting fluid or lubricant. This can help reduce friction and heat during the cutting process, prolonging the life of the cutter and achieving a smoother cut.

-

Inspect the Cut: Once you have completed the cut, inspect the Nitinol to ensure it has been cleanly and precisely cut to your specifications. If any rough edges or burrs are present, you can use fine files or abrasive materials to smooth them out.

-

Maintenance: After use, clean the Excelta carbide cutter and store it properly to maintain its cutting efficiency. Proper maintenance ensures that your cutter remains effective for future use.

In conclusion, when working with Nitinol, using Excelta carbide cutters is a reliable choice for achieving precise and clean cuts. Remember to prioritize safety, select the appropriate cutter, and use controlled pressure during the cutting process. With the right tools and techniques, you can harness Nitinol's unique properties to create intricate medical devices and components that contribute to the continued advancement of healthcare technology.

For over 40 years, Lab Pro Inc. has been committed to delivering the highest quality nitinol cutting tools such as Excelta carbide insert cutters, lab supplies, lab equipment, reagents, distance learning kits, and cleanroom PPE apparel. Renowned by global medical device companies and laboratories, we ensure exceptional quality in every product. Contact us online or call 888-452-2776 to learn more. Discover top-notch lab supplies and elevate your experiments today!